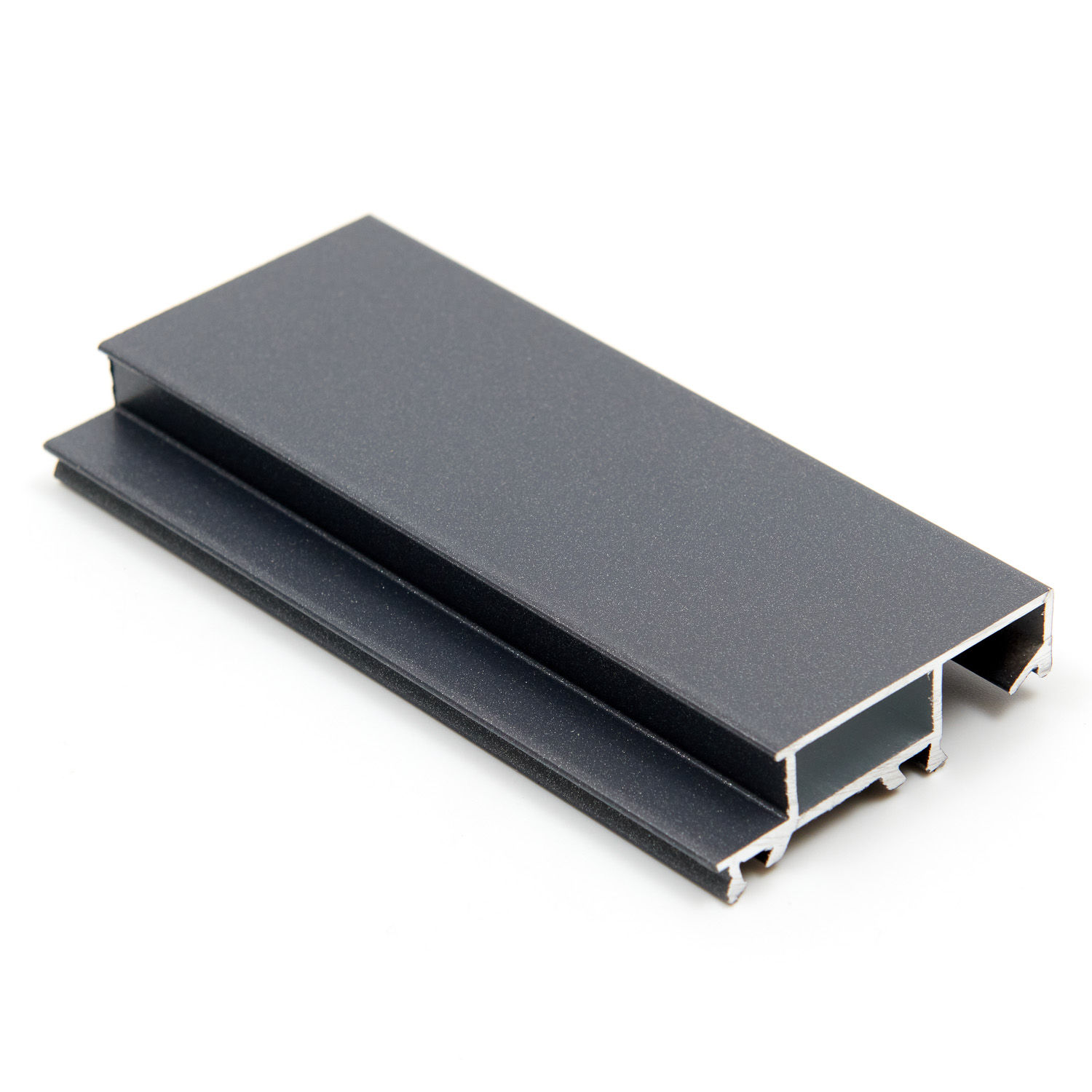

Industrial aluminum profile is a kind of aluminum as the main component of the alloy material, aluminum rod through hot melt, extrusion to get different cross-section of aluminum material, but the proportion of the added alloy is different, the production of industrial aluminum profile mechanical properties and application fields are also different.

First, the characteristics of industrial aluminum profiles:

- Non-ferromagnetic

- Machinability

- Formability

- Recyclability

- Corrosion resistance

Second, the processing method of industrial aluminum profiles:

The processing method of industrial aluminum profiles can be from two perspectives, one is that the profiles are extruded from raw materials into aluminum profiles of different sections, but the model specifications are selected and processed on the aluminum profiles themselves, such as punching, tapping, etc.

1, oxidation processing. The surface of industrial aluminum profiles is treated with silver oxidation, which is elegant and beautiful and resistant to corrosion.

2, extrusion molding. Each specification of aluminum profile has a corresponding production mold, the aluminum material is put into the mold, and the aluminum profile you need is formed by extrusion.

3, casting molding. Have you seen the ancient craft of blacksmithing? The casting molding of industrial aluminum profiles is similar to this.

4, smelting impurities. The higher the purity of aluminum, the better the performance. So through the melting furnace to remove impurities, to increase the performance of aluminum profiles.

5, ingredients to increase the hardness of the product. We know that industrial aluminum profile is an aluminum alloy profile, there are aluminum magnesium silicon alloy, aluminum zinc alloy and so on. This can increase the hardness and bearing capacity of the aluminum profile.